Understanding Generative AI

Generative AI refers to a category of artificial intelligence systems that are capable of producing content, designs, or data that resemble human creations. At its core, generative AI relies on sophisticated algorithms and machine learning models designed to analyze vast datasets. These models learn from existing data and generate innovative outputs, often pushing the boundaries of creativity and functionality. In the context of engineering and manufacturing, generative AI plays a pivotal role in revolutionizing the design process, especially for components like spare parts.

The technology underpinning generative AI includes various approaches such as neural networks, evolutionary algorithms, and reinforcement learning. Neural networks, for instance, are designed to mimic the way the human brain processes information, enabling the AI to learn from complex patterns. Evolutionary algorithms simulate the process of natural selection, allowing designs to evolve over generations to achieve optimal results. Reinforcement learning empowers machines to learn from trial and error, refining their outputs based on feedback. As a result, these technologies afford engineers the ability to explore numerous design possibilities in a fraction of the time it would take using traditional methods.

Beyond spare parts design, generative AI finds applications across various domains including architecture, product design, and even digital art. In architecture, for instance, it aids in the creation of efficient building layouts by optimizing spatial arrangements. In product design, generative algorithms can help companies innovate by addressing specific performance criteria, thus enhancing the end-user experience. Furthermore, the historical context leading to the advent of generative design highlights the evolution of computational capabilities. With advancements in processing power and storage capacity, the once-impractical task of generating complex designs has become feasible, paving the way for widespread adoption across multiple industries.

Advantages of Generative AI in Spare Parts Design

Generative AI has emerged as a transformative force in the realm of spare parts design, offering numerous advantages that significantly enhance the design process. One of the foremost benefits is the ability to foster innovation. By leveraging algorithms that evaluate vast datasets, engineers can explore an extensive range of design alternatives, often uncovering creative solutions that traditional methods may overlook. This capability not only stimulates innovative thinking but also allows for the development of spare parts that can outperform existing designs in various performance metrics.

Cost savings represent another critical advantage of generative AI in spare parts design. Through optimization techniques, generative design can reduce material usage without compromising the integrity of the parts. This decreased material consumption translates into lower manufacturing costs, as well as less waste, making the process more economically viable. Moreover, the efficiency of design cycles is markedly improved; generative AI enables rapid prototyping and swift iterations, leading to quicker turnaround times from concept to production.

Furthermore, the implementation of generative AI in design contributes to sustainability efforts within the manufacturing sector. The technology aids engineers in crafting lightweight designs that do not sacrifice strength and durability, which is essential for high-performance applications. At the same time, the reduction in material waste and the potential for more energy-efficient production methods promote an environmentally friendly approach to manufacturing. As companies increasingly prioritize sustainable practices, the integration of generative AI will play a pivotal role in shaping the future of spare parts design.

In conclusion, the advantages of generative AI in spare parts design encompass enhanced innovation, significant cost savings, improved efficiency, and a sustainable approach to manufacturing. By harnessing these benefits, organizations can achieve optimal design solutions that not only meet performance standards but also align with contemporary environmental objectives.

Challenges and Considerations in Implementation

The integration of generative AI into spare parts design processes presents a variety of challenges that organizations must navigate. One of the foremost concerns is the requirement for skilled personnel who can interpret the designs generated by AI technologies. While generative AI can produce innovative solutions, the complexity of these designs often necessitates human expertise for evaluation and refinement. This creates a demand for training programs and strategies to upskill existing staff or acquire new talent proficient in both design principles and AI interpretation.

Intellectual property rights also emerge as a critical consideration in the implementation of generative AI. The ownership of AI-generated designs can be ambiguous, leading to potential disputes over who retains rights to a particular design or concept. Organizations must establish clear policies that address these intellectual property issues, which may include agreements on design attribution and the use of proprietary data in the development of AI models.

Furthermore, the integration of generative AI into existing workflows poses operational challenges. Organizations need to carefully assess how new AI technologies can complement and enhance their traditional design methodologies without causing disruption. This may involve reengineering existing processes to be AI-compatible, which can demand substantial financial investment and a considerable adjustment period for employees.

Data quality is another fundamental aspect that influences the effectiveness of generative AI in spare parts design. The algorithms rely heavily on the input data’s accuracy and relevance; thus, poor-quality data can lead to suboptimal design outcomes. It is essential for organizations to prioritize data cleansing and management practices during the implementation phase. Lastly, ethical implications must also be considered, particularly regarding algorithmic bias and implications for employment in the design and manufacturing sectors. Addressing these potential biases is crucial to ensure equitable and just outcomes as AI technologies continue to advance.

Future Trends in Generative AI for Spare Parts Design

The landscape of spare parts design is poised for a transformative shift, driven by the rapid evolution of generative AI. As industries increasingly adopt this technology, several trends are starting to emerge, heralding a new era in design processes. One significant trend is the advancement in materials science, which is a crucial component in optimizing spare parts. New materials, such as composites and bio-based substances, can influence design parameters, allowing for enhanced performance, reduced weight, and improved durability. Generative AI can swiftly analyze these new material properties, leading to innovative designs that fulfill specific performance requirements.

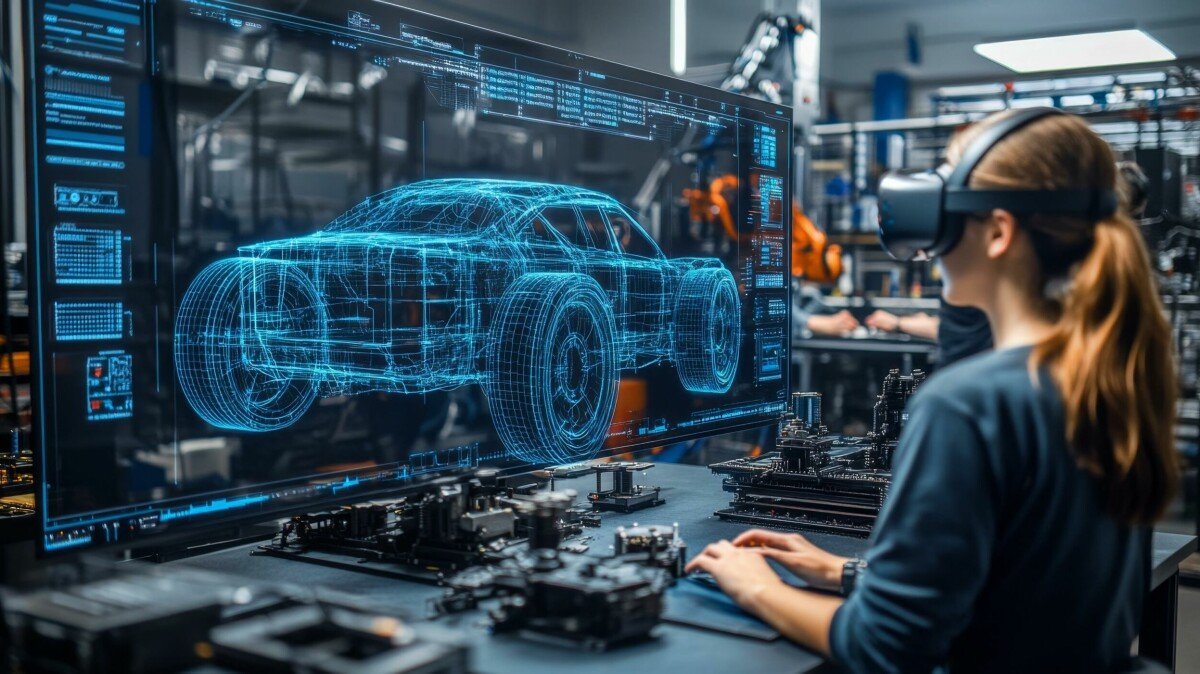

Collaboration between generative AI systems and human designers is another key trend that is expected to gain traction. As AI becomes more integrated into the design process, the role of human professionals will evolve from traditional design tasks to oversight and curation of AI-generated solutions. Collaborative AI systems are anticipated to assist designers by providing real-time feedback, suggesting design alternatives, and ensuring compliance with industry standards. This synergy will ultimately facilitate more efficient workflows and reduce the time required to bring products to market.

In the context of digital manufacturing, generative AI is increasingly expected to operate in conjunction with other leading-edge technologies, such as the Internet of Things (IoT) and blockchain. IoT devices can provide real-time data about machinery and processes, which generative AI can analyze to optimize designs accordingly. Meanwhile, blockchain technology may offer enhanced traceability and transparency in the supply chain, ensuring that spare parts are designed and produced in compliance with regulatory requirements. The integration of generative AI with these technologies is likely to reshape the manufacturing landscape, catering to evolving customer needs and driving innovation in spare parts design in the years to come.