Introduction to the Auto Industry Survey

The recent survey conducted within the auto industry offers a comprehensive overview of shifting trends, which have become increasingly significant for stakeholders in the sector. The primary purpose of this research was to gather insights from factories worldwide, focusing on their operational methodologies and the evolving dynamics that affect their productivity. The survey encompassed a wide range of manufacturing entities, including traditional automotive manufacturers and emerging electric vehicle producers, thus ensuring a robust representation of the industry.

Understanding factory trends is critical as it can significantly impact various aspects of the auto industry. The findings of the survey provide valuable information on manufacturing efficiency, which is vital for maintaining competitiveness. Stakeholders, such as investors, manufacturers, and policymakers, rely on these insights to make informed decisions regarding innovation, resource allocation, and economic viability. As the industry faces numerous challenges, including supply chain disruptions and the shift towards sustainable practices, being attuned to these trends becomes imperative.

The survey aimed to address several key questions that reflect the changing landscape of the auto industry. These inquiries covered topics such as the adoption of advanced manufacturing technologies, the integration of sustainable practices, and the workforce dynamics in factories. Participants from diverse demographics, including industry experts, factory management, and production staff, contributed to the breadth of responses, ensuring that a variety of perspectives were captured.

As we delve deeper into the findings, it is essential to recognize the critical implications of these trends on future manufacturing strategies and the overall direction of the auto sector. The insights gleaned from this survey set the groundwork for understanding how factory operations are adapting to meet the demands of a rapidly evolving market.

Current Trends in Factory Operations

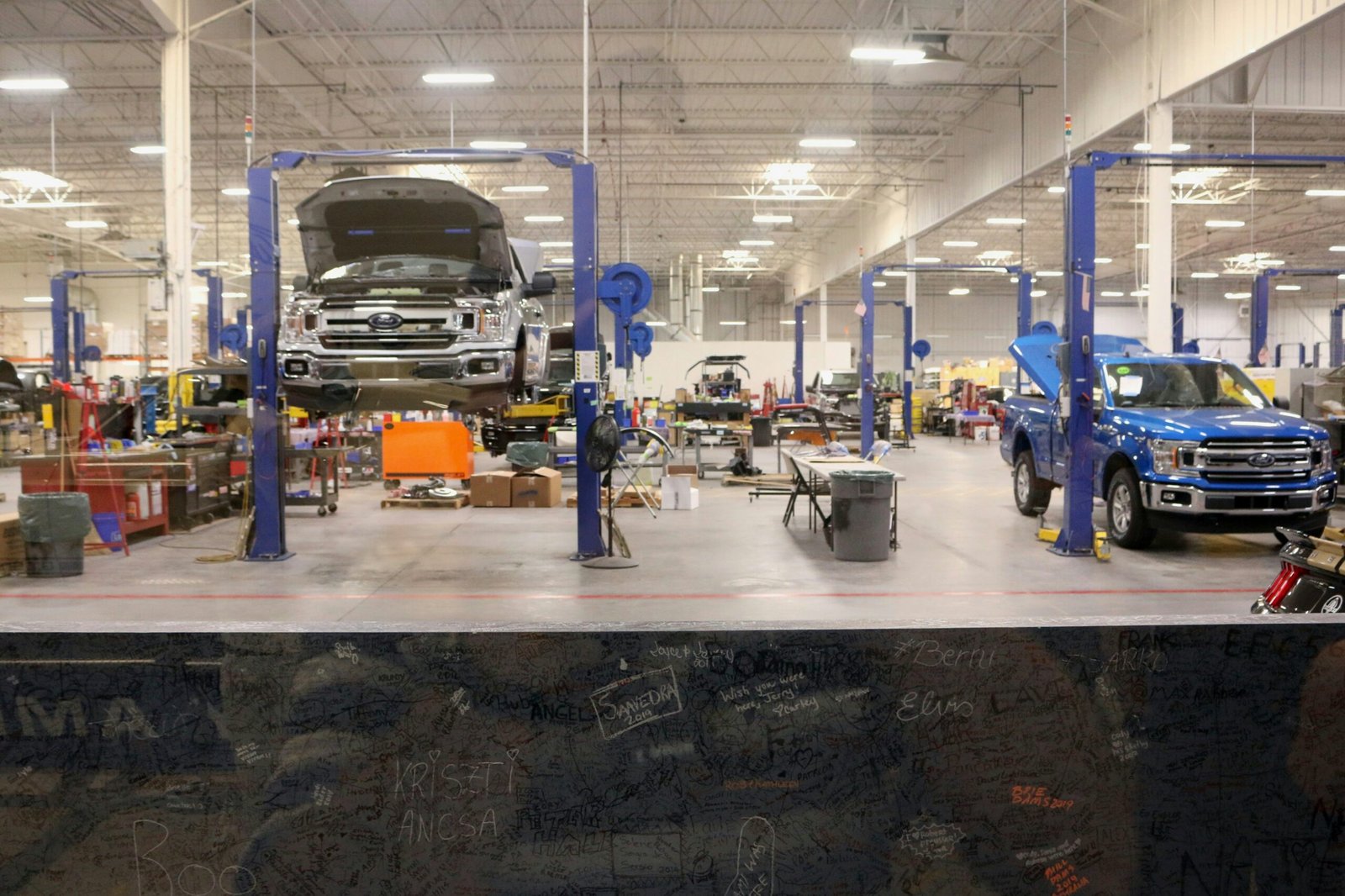

The automobile industry is undergoing a notable transformation, as highlighted by a recent survey that reveals key operational trends prevalent in factories worldwide. One of the most significant shifts is the adoption of advanced production methods. Traditional conveyor belt systems are increasingly being replaced by more flexible manufacturing processes that allow for customization and rapid adaptation to consumer demands. This evolution enhances efficiency and responds more adeptly to the fluctuating market conditions.

Automation and robotics have become integral components of modern auto factories, streamlining operations and significantly reducing production times. The introduction of robotic arms, automated guided vehicles (AGVs), and collaborative robots (cobots) not only improves productivity but also ensures higher precision in assembly tasks. Factories are also increasingly embracing artificial intelligence (AI) and the Internet of Things (IoT) to facilitate real-time data analysis and communication. These technologies allow manufacturers to monitor equipment performance, predict maintenance needs, and optimize inventory management, which ultimately leads to cost savings and enhanced operational efficiency.

Concurrent with these advancements is a dramatic shift towards sustainable manufacturing practices. Many factories are prioritizing eco-friendly initiatives by utilizing renewable energy sources, reducing waste, and implementing circular economy principles. For instance, major automotive brands are investing in battery recycling programs and exploring alternative materials that reduce the environmental impact of vehicle production. These efforts not only align with global environmental goals but also resonate with a consumer base that increasingly values sustainability.

In conclusion, the current trends in factory operations are heavily characterized by a robust intertwining of automation, innovative technologies, and sustainable practices. As auto manufacturers continue to adapt to these changing dynamics, the industry is set to witness a profound transformation in production strategies that would redefine the future of automobile manufacturing.

Challenges Faced by Auto Factories

The automotive industry is currently navigating a complex array of challenges that impact the operations of auto factories worldwide. Among these, supply chain disruptions stand out as particularly significant, exacerbated by global events such as the COVID-19 pandemic and geopolitical tensions. The interruption of essential components has forced many manufacturers to reevaluate their sourcing strategies, leading to delayed production schedules and increased operational expenses.

Rising material costs present another pressing challenge for auto factories. Prices for key inputs like steel, aluminum, and semiconductor chips have surged, placing additional financial strain on manufacturers. This escalation not only affects profit margins but also compels factories to explore alternative materials and innovative manufacturing processes to mitigate unanticipated costs. In response, many manufacturers are adopting more localized supply chains as a means to alleviate dependency on distant suppliers and reduce exposure to volatile global markets.

Furthermore, workforce shortages have emerged as a critical issue for automotive factories. The challenge stems from a combination of factors, including an aging workforce, the demand for new skill sets due to technological advancements like automation and electrification, and the competitive labor market. To combat these shortages, many manufacturers are investing in training programs aimed at upskilling their current workforce and attracting new talent, particularly in high-demand areas such as robotics and software development.

Additionally, regulatory changes are influencing factory operations. Increased scrutiny over environmental impact and stringent efficiency standards require factories to adapt their processes and technologies. To meet these regulatory demands, many manufacturers are implementing sustainable practices and advanced manufacturing technologies, ultimately aiming to improve efficiency while complying with the evolving legal landscape.

In light of these challenges, auto factories are demonstrating resilience and adaptability, employing diversified strategies to not only survive but thrive in a tumultuous market. These approaches are essential for maintaining production capacities and ensuring the long-term viability of the manufacturing sector within the automotive industry.

Future Outlook: Where is the Auto Industry Heading?

The automotive industry is currently undergoing a profound transformation, influenced by technology advancements, evolving consumer preferences, and varying economic conditions. As manufacturers navigate this dynamic landscape, several key trends are anticipated to reshape the future of auto factories across the globe.

One of the most prominent trends is the shift towards electric and hybrid vehicles. Increasing regulatory pressures to reduce emissions and growing consumer demand for sustainable transportation are driving this change. Auto manufacturers are investing heavily in battery technology and electric vehicle (EV) production capabilities, which necessitate the reconfiguration of existing factory infrastructures. As a result, we will likely see a significant rise in the number of facilities dedicated solely to the production of EVs, as companies prioritize environmental considerations alongside profitability.

Moreover, the integration of advanced technologies such as artificial intelligence, automation, and the Internet of Things (IoT) within factory operations is expected to enhance efficiency and productivity. By utilizing smart manufacturing systems, companies can optimize their production processes, reduce operational costs, and improve quality control. These innovations not only allow for greater customization of vehicles but also facilitate quicker response times to changing market demands.

Additionally, the rise of connected vehicles is influencing the factory landscape. As vehicles become increasingly integrated with digital technologies, manufacturers will need to adapt their production processes to incorporate enhanced connectivity features. This trend emphasizes the importance of agility and innovation within factories, as automakers strive to stay competitive in a rapidly changing marketplace.

In conclusion, the auto industry is poised for significant shifts in the coming years, driven by advancements in technology, changing consumer behaviors, and economic challenges. Manufacturers that embrace flexibility and innovation will likely be best positioned to respond to these developments and sustain their competitive edge in an evolving industry.