Introduction to Chemical Process Optimization

Chemical process optimization is a critical practice within the chemical industry, focusing on enhancing the efficiency and efficacy of production processes. This practice involves the systematic refinement of operations to achieve the desired output levels while minimizing resource consumption, waste generation, and production costs. By optimizing chemical processes, companies can significantly improve their competitive edge and ensure sustainability in their operations. It encompasses a range of activities, from reaction pathway selections to equipment configurations, all aimed at maximizing yield and product quality.

Historically, the quest for optimization in chemical processes has relied heavily on established methodologies, including trial-and-error experiments and heuristic approaches. While these traditional methods have yielded improvements over the years, they often fall short in delivering the rapid and significant changes required to meet the dynamic demands of the market. Engineers and scientists face several challenges when optimizing these processes, including the inherent complexity of chemical reactions, the multitude of variables involved, and limitations in data analysis capabilities. As a result, achieving optimum performance typically requires extensive time and resources, making it a labor-intensive endeavor.

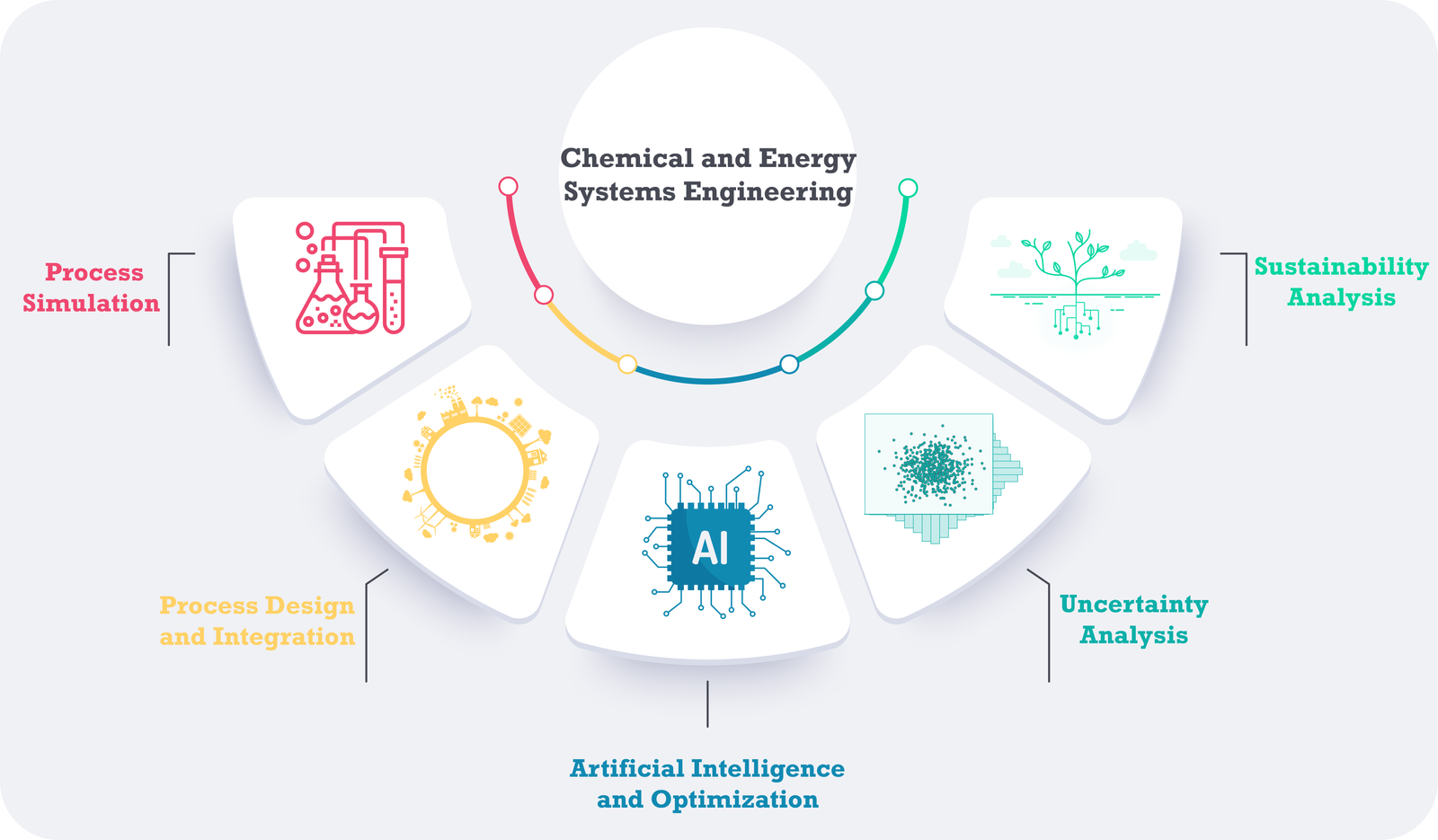

The advent of artificial intelligence (AI) promises to address many of the challenges associated with traditional process optimization. By harnessing machine learning algorithms and advanced data analytics, AI can analyze vast datasets derived from chemical processes, identifying patterns and relationships that may not be evident through conventional methods. This technological revolution has the potential to streamline optimization efforts, offering real-time insights and recommendations that improve decision-making. As companies increasingly adopt these AI-driven strategies, they stand to benefit from enhanced efficiency, reduced operational costs, and improved product quality, marking a significant departure from traditional optimization practices.

The Role of AI Technologies in Optimization

Artificial Intelligence (AI) technologies are playing an increasingly pivotal role in the optimization of chemical processes, driving a transformation in how the industry analyzes, predicts, and enhances operational efficiencies. Among the various AI techniques, machine learning, deep learning, and predictive analytics stand out as key players in this evolving field. These technologies are capable of processing and analyzing large datasets generated during chemical production, enabling manufacturers to derive insights that were previously difficult or impossible to obtain.

Machine learning algorithms, for instance, can identify patterns and trends within complex datasets, facilitating more informed decision-making in chemical production. By employing techniques such as supervised and unsupervised learning, these algorithms help to minimize variances in production processes and enhance product quality. Another widely used AI technology, deep learning, leverages neural networks to improve the accuracy of predictions regarding chemical reactions and product yield. This approach is particularly beneficial in scenarios involving non-linear relationships and high-dimensional data typical in chemical engineering.

Predictive analytics, another vital component of AI, utilizes statistical algorithms and machine learning techniques to forecast outcomes based on historical data. In the context of chemical process optimization, predictive analytics can anticipate equipment failures, optimize scheduling, and enhance resource allocation. This not only improves efficiency but also contributes to cost reductions and environmental sustainability.

Several case studies have exemplified the successful integration of these AI technologies in chemical manufacturing. For example, companies have reported significant enhancements in productivity and reductions in waste through the application of machine learning models that dynamically adjust process parameters. Such implementations underscore the transformative potential of AI in revolutionizing chemical process optimization, paving the way for smarter, more efficient manufacturing practices.

Benefits of AI-Driven Chemical Process Optimization

Artificial intelligence (AI) has emerged as a transformative force in many industries, including chemical processing. One of the most profound benefits of AI-driven chemical process optimization is the ability to significantly increase production rates. By utilizing advanced algorithms and machine learning, AI can analyze vast amounts of data to identify optimal operating conditions and adjust them in real-time. This leads to enhanced efficiency in chemical reactions and, subsequently, higher output levels.

In addition to boosting production, AI plays a crucial role in reducing energy consumption. By optimizing process parameters, AI helps minimize energy waste, allowing facilities to operate more sustainably. Efficient energy usage not only translates to cost savings but also contributes to a decrease in the carbon footprint of chemical manufacturing. This is particularly important as industries around the globe increasingly face pressure to adopt greener practices and prioritize sustainability.

Another significant advantage of AI integration in chemical processes is the effective reduction of waste generation. Traditional processes can be fraught with inefficiencies that lead to excess materials being used and wasted. AI technologies can streamline operations, ensuring that resources are utilized more effectively, thereby minimizing the quantity of waste produced. This optimization not only has positive environmental implications but can also enhance compliance with stringent regulations concerning waste management.

Furthermore, the economic benefits resulting from AI-driven optimization are noteworthy. With lower operational costs due to efficient resource management and improved yields, companies can experience a boost to their profitability. As businesses strive to adapt to a competitive marketplace, embracing AI-driven solutions becomes increasingly important for maintaining economic viability while fostering eco-friendly practices.

Future Trends and Challenges in AI for Chemical Process Optimization

The field of chemical process optimization is on the brink of a transformative evolution, driven largely by advancements in artificial intelligence (AI). Future trends indicate a growing integration of AI technologies with the Internet of Things (IoT) and automation systems, which are set to revolutionize the industry. This integration will facilitate real-time data collection and analysis, leading to more responsive and adaptive processes. Chemical plants equipped with IoT sensors will be able to harness vast volumes of data, which AI systems can analyze promptly to optimize operations and improve efficiency.

In tandem with the emergence of IoT, the implementation of machine learning and deep learning algorithms is becoming increasingly vital in predictive maintenance, operational efficiency, and quality assurance within chemical processes. These AI-driven tools can learn from historical data, making predictions and adjustments that enhance overall productivity and reduce downtime. However, the path forward is not without challenges. The complexity of integrating advanced AI technologies into existing chemical processing frameworks poses significant hurdles. Businesses must not only invest in new software and hardware but also ensure that their personnel are equipped with the necessary skills to operate these sophisticated systems.

Moreover, data privacy and security remain pressing concerns. Chemical manufacturers must grapple with how to safeguard sensitive data while maximizing the potential of AI applications. As these technologies evolve, there will also be a growing demand for continuous learning algorithms that adapt to new data streams and changing process conditions. Ensuring that AI systems can evolve without human intervention will be crucial for maintaining competitive advantages. As the chemical industry moves toward greater reliance on AI, preparing for these trends and challenges is essential. By focusing on strategic investments in technology and human capital, companies can leverage AI’s full capabilities, paving the way for a more efficient and innovative future in chemical process optimization.