Introduction to AI in Mechanical Systems

Artificial Intelligence (AI) has emerged as a game changer across various sectors, and its relevance in mechanical systems is particularly noteworthy. Mechanical systems, which encompass a wide range of machines and structures, are often confronted with complex optimization challenges. The integration of AI technologies, such as machine learning and data analytics, into these systems holds the potential to significantly enhance their performance and efficiency.

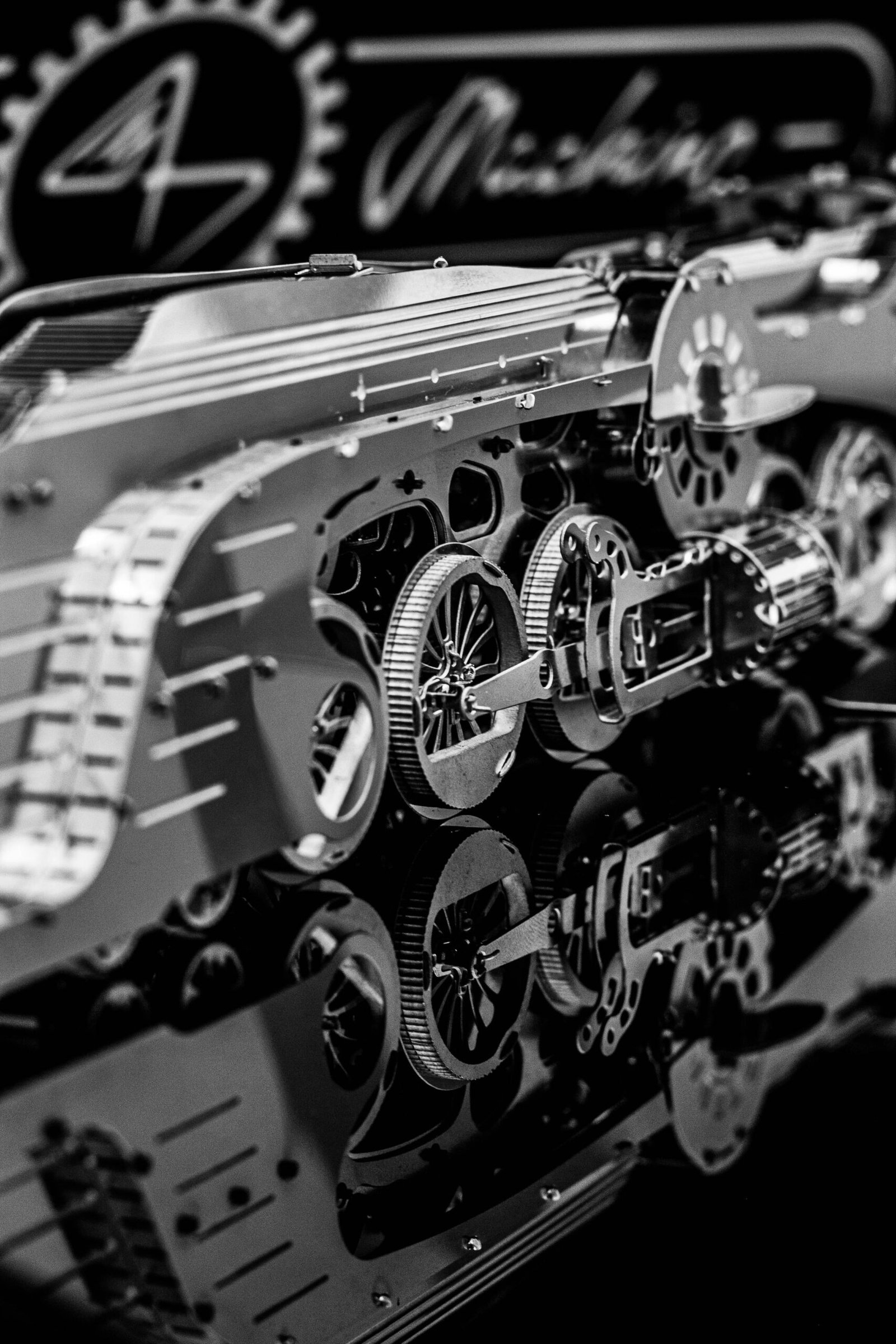

Mechanical systems typically involve processes or devices that require constant monitoring and adjustment to ensure optimal operation. These systems can include anything from automotive engines and manufacturing equipment to robotics and HVAC systems. The complexity associated with modern mechanical systems often presents significant hurdles in optimization. Factors such as material wear, energy consumption, and operational consistency must be taken into account, which can complicate the design and maintenance processes.

AI technologies provide innovative solutions to these challenges by enabling systems to learn from data and improve over time. For instance, machine learning algorithms can analyze vast amounts of data generated by mechanical systems, identifying patterns that might not be evident to human operators. This capability allows for predictive maintenance, where potential issues can be identified before they lead to failures, ultimately enhancing reliability and reducing downtime.

Moreover, data analytics can help in understanding and minimizing energy consumption in mechanical systems. By implementing AI-driven models, engineers can optimize various parameters to improve performance while adhering to sustainability standards. As we delve deeper into the implications of AI in mechanical systems, it is crucial to recognize that the synergy between AI technologies and mechanical engineering paves the way for innovative solutions in the quest for optimization.

Applications of AI in Mechanical System Optimization

Artificial intelligence (AI) has emerged as a pivotal technology in the realm of mechanical system optimization, influencing various industries through its applications. One significant area where AI proves beneficial is predictive maintenance. Traditional maintenance approaches often involve periodic inspections or reactive measures following a failure; however, AI algorithms analyze data from sensors embedded within mechanical components to predict potential failures before they occur. This predictive capability enables organizations to schedule maintenance activities more effectively, thus reducing downtime and operational costs.

Design optimization is another crucial application where AI can enhance mechanical system performance. By leveraging machine learning algorithms, engineers can explore vast design spaces and generate innovative solutions that are often overlooked in conventional design processes. AI aids in evaluating numerous design variables simultaneously, allowing for an optimized configuration that meets stringent performance criteria while minimizing material use. This not only leads to more efficient products but also contributes to sustainability goals by reducing waste and resource consumption.

Real-time monitoring is integral to maintaining the efficiency of mechanical systems, and AI plays a vital role in this regard. Through continuous data collection and analysis, AI systems can provide immediate insights into the operational status of machinery. For instance, in the automotive and aerospace sectors, AI-driven monitoring systems ensure that vehicles and aircraft operate within specified parameters, thus enhancing safety and maintaining performance. Moreover, the integration of AI with the Internet of Things (IoT) further amplifies these capabilities, facilitating smarter, more responsive manufacturing processes.

The impact of AI-driven optimization can be observed across various sectors, including automotive, aerospace, and manufacturing, where operational efficiency, cost reduction, and the longevity of mechanical components have been significantly enhanced. Such advancements underline the transformative power of AI, reinforcing its role as a cornerstone for future innovations in mechanical engineering.

Challenges and Limitations of Implementing AI in Mechanical Systems

The integration of artificial intelligence (AI) into mechanical systems presents numerous challenges and limitations that organizations must address. One of the primary obstacles is the quality and availability of data. AI models rely heavily on large volumes of high-quality data for training and decision-making processes. If the data collected is insufficient, inconsistent, or biased, it can lead to suboptimal performance and inaccurate predictions. Thus, organizations must invest in robust data collection and preprocessing methods to ensure the effectiveness of AI systems.

Another significant challenge is the complexity of AI algorithms. Many organizations may lack the technical proficiency required to develop, deploy, and interpret AI solutions effectively. This requires cross-disciplinary expertise, incorporating skills from mechanical engineering, computer science, and data analytics. The shortage of professionals who possess this multifaceted knowledge can hinder progress and slow down the implementation of AI technologies in mechanical systems.

Moreover, there is often resistance to change within organizations when introducing AI solutions. Employees may be apprehensive about job security or hesitant to adopt new technologies due to a lack of understanding. To overcome this barrier, organizations should engage in change management strategies that include comprehensive training programs and clear communication about the benefits of AI integration.

Ethical considerations also pose a challenge when implementing AI in mechanical systems. Ensuring data privacy and security is paramount, as sensitive information may be collected and analyzed during the AI process. Organizations must adhere to regulatory standards and develop guidelines that protect user data while promoting ethical AI practices. Addressing these complexities is essential for fostering a successful transition to AI-driven mechanical systems.

Future Trends in AI and Mechanical System Optimization

The landscape of mechanical system optimization is rapidly evolving, propelled by advancements in artificial intelligence (AI) technologies. Emerging innovations such as advanced robotics, digital twins, and enhanced AI algorithms are set to redefine the methodologies engineers use to optimize mechanical systems. These technologies not only streamline processes but also allow for more accurate simulations and predictive analyses, which can lead to significant improvements in efficiency and performance.

Advanced robotics are increasingly being integrated into mechanical systems, allowing for greater precision and adaptability. These robots can execute complex tasks autonomously, thereby enhancing productivity while reducing the risk of human error. As AI continues to evolve, it is anticipated that the capabilities of these robotic systems will expand, enabling them to learn from their environments and improve their operational algorithms in real-time.

Digital twins represent another revolutionary trend in mechanical system optimization. By creating a digital replica of a physical system, engineers can perform simulations and test various scenarios without incurring the high costs associated with physical prototypes. The predictive analytics offered by AI can further enhance the digital twin experience, allowing for ongoing optimization and real-time adjustments based on data collected from the physical counterpart.

As we gaze into the future, the role of engineers will inevitably shift due to the integration of AI technologies. Continuous learning and adaptation will become paramount, as professionals in the mechanical field must equip themselves with new skills to work effectively alongside advanced systems. Understanding AI’s underlying mechanisms will better position engineers to oversee, troubleshoot, and innovate within their domains. The collaboration between human expertise and AI-driven insights promises to foster a new era of mechanical optimization, paving the way for more sustainable and efficient practices.