Introduction to Nanotechnology in Coatings

Nanotechnology represents a significant advancement in material science, characterized by manipulating matter at the atomic and molecular levels, specifically within the size range of 1 to 100 nanometers. This technology has found a remarkable intersection with coatings, leading to the development of nanotech coatings that offer superior properties compared to their conventional counterparts. These coatings incorporate nanoparticles—tiny particles with unique properties that emerge at nanoscale—allowing for enhanced performance in various industrial applications.

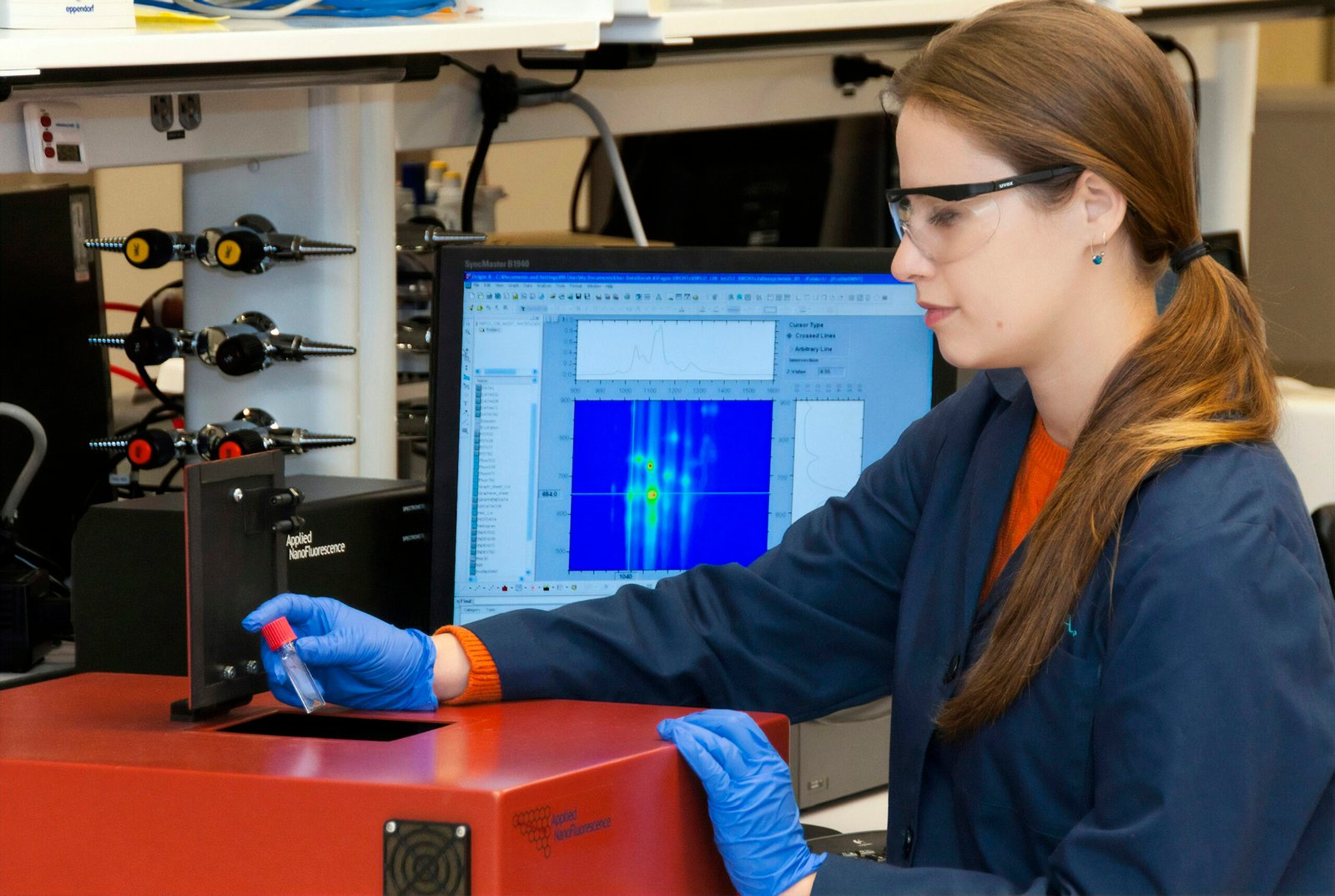

At its core, a nanotech coating refers to a coating that utilizes nanoparticles integrated into its formulation. These particles impart beneficial characteristics such as increased strength, durability, and resistance to corrosion and wear. The fundamental principles of nanotechnology enable the enhancement of traditional coatings, which often suffer from limitations like lower stability and limited functional properties. By leveraging nanoparticles such as silica, titanium dioxide, and carbon nanotubes, manufacturers can significantly improve the mechanical, thermal, and chemical properties of the coatings.

The evolution of coating technologies is a testament to the increasing relevance of nanotech applications. Historically, conventional coatings have been employed for protective and aesthetic purposes; however, with the introduction of nanotechnology, there is a growing focus on performance-driven solutions. Industries ranging from automotive to aerospace are now utilizing these innovative coatings, largely due to the advantages they offer, including extended lifespan, reduced maintenance costs, and enhanced operational efficiency. Consequently, nanotech coatings are becoming indispensable in safeguarding industrial assets against harsh environments and improving the overall performance of products.

Types of Nanotech Coatings and Their Properties

Nanotech coatings have gained significant importance in industrial applications due to their enhanced properties and protective capabilities. Among the various types available, anti-corrosive, hydrophobic, and antimicrobial coatings stand out, each offering unique benefits that contribute to improved performance in challenging environments.

Anti-corrosive coatings are designed to prevent corrosion by creating a protective barrier on the surface of materials. These coatings utilize nanoparticles that significantly increase the surface area, which enhances the coating’s ability to resist oxidation and degradation. This increased effectiveness is crucial in industries like marine and oil and gas, where materials are frequently exposed to harsh environmental conditions. Aside from corrosion resistance, these coatings often have a longer lifespan compared to traditional coatings, resulting in lower maintenance costs.

Hydrophobic coatings, on the other hand, repel water and other liquids, making surfaces easier to clean and maintain. This property is achieved through the application of nanoparticles that create a textured surface, which reduces the contact area with liquids. Industries such as construction and automotive benefit greatly from hydrophobic coatings, as they help to prevent buildup of dirt, grime, and moisture, ultimately enhancing the longevity of the material and improving safety due to reduced slip hazards.

Antimicrobial coatings focus on inhibiting the growth of bacteria and other pathogens on surfaces. By incorporating nanoparticles with antimicrobial properties, these coatings are particularly valuable in healthcare settings, food processing, and other environments where hygiene is paramount. The enhanced reactivity of nanoparticles enables these coatings to actively kill bacteria upon contact, thereby reducing the risk of contamination and infection.

Overall, the diverse types of nanotech coatings provide significant advantages, including durability, chemical resistance, and ease of cleaning, empowering industries to operate efficiently and safely in demanding conditions. The transition to nanotech coatings illustrates the industry’s commitment to leveraging technology for enhanced performance and protection.

Industrial Applications of Nanotech Coatings

Nanotech coatings have emerged as a transformative technology across various industries, providing enhanced protection and performance. One of the most significant sectors benefiting from nanotech advancements is aerospace. These coatings are utilized on aircraft surfaces to minimize drag, enhance fuel efficiency, and protect against environmental factors such as corrosion and UV radiation. For instance, a leading aerospace manufacturer implemented a nanotech coating that reduced maintenance downtime by 30%, demonstrating both operational efficiency and cost-effectiveness.

In the automotive industry, nanotech coatings are increasingly applied to protect vehicles from scratches, chemical damage, and environmental contaminants. By using hydrophobic and self-cleaning properties, these coatings help maintain the aesthetic appeal of vehicles while extending the lifespan of surfaces. A notable case study highlighted how a major car manufacturer integrated nanotech coatings into their production process, which subsequently resulted in a 20% reduction in paint defect rework, showcasing improved quality control.

The electronics sector also finds significant value in nanotech coatings. These coatings serve to enhance the durability and performance of electronic devices by providing water and dust resistance. For example, a prominent smartphone brand adopted nanotech coatings to improve their devices’ resilience against liquid exposure, resulting in fewer warranty claims and increased customer satisfaction. The implementation of these coatings not only bolsters device integrity but also supports the overall sustainability initiatives within the electronics industry.

Furthermore, in the construction industry, nanotech coatings are applied to surfaces such as concrete and metal structures to enhance durability and reduce maintenance requirements. These coatings often include antimicrobial properties, which promote safety and hygiene in public spaces. A case study from a major construction project illustrated that the use of nanotech coatings led to a significant decrease in maintenance costs over a five-year period, underscoring both environmental and economic benefits.

Overall, nanotech coatings play a crucial role in various industrial applications by improving operational efficiency, enhancing safety, and contributing to environmental sustainability.

Future Trends and Challenges in Nanotech Coatings

As the realm of nanotechnology continues to advance, the future of nanotech coatings appears promising, with ongoing research paving the way for innovative applications across various industrial sectors. These cutting-edge coatings leverage nanomaterials to enhance properties such as durability, resistance to wear, and chemical stability, thus significantly improving performance parameters. Emerging technologies, including self-healing coatings and multifunctional surfaces, are set to redefine how industries approach material protection. By integrating these novel properties into nanotech coatings, manufacturers can offer solutions that not only protect against environmental factors but also actively respond to damage.

However, the advancement of nanotech coatings is accompanied by several challenges. Regulatory hurdles present significant obstacles for manufacturers aiming to introduce new products into the market. The complexity of evaluating the safety and effectiveness of nanomaterials demands thorough research and validation, which can delay product commercialization. Additionally, the high costs associated with the development and application of advanced nanotech coatings could hinder broader adoption, particularly among small and medium-sized enterprises with limited budgets.

Public perception also plays a critical role in shaping the future of nanotech coatings. Misinformation and misunderstanding surrounding nanotechnology can lead to skepticism among consumers and regulatory bodies alike. Educating stakeholders about the benefits and safety of nanotech coatings is essential to foster trust and acceptance. Furthermore, as industries push for innovation, a balance must be struck between advancing technology and maintaining safety and environmental stewardship. The integration of sustainability practices into the development of nanotech coatings will be crucial in ensuring that the benefits do not come at an ecological cost.

In conclusion, while the prospects for nanotech coatings in industrial applications are bright, careful navigation of the associated challenges will determine the pace and success of this technology’s adoption.