Introduction to Additive Manufacturing in Aerospace

Additive manufacturing (AM), commonly recognized as 3D printing, has emerged as a transformative technology within the aerospace sector. Unlike traditional manufacturing methods that rely on subtractive processes, where materials are cut away from a solid block, additive manufacturing builds components layer by layer, allowing for intricate designs that were previously unattainable. This shift not only enhances design flexibility but also aligns with the industry’s goals of sustainability and efficiency.

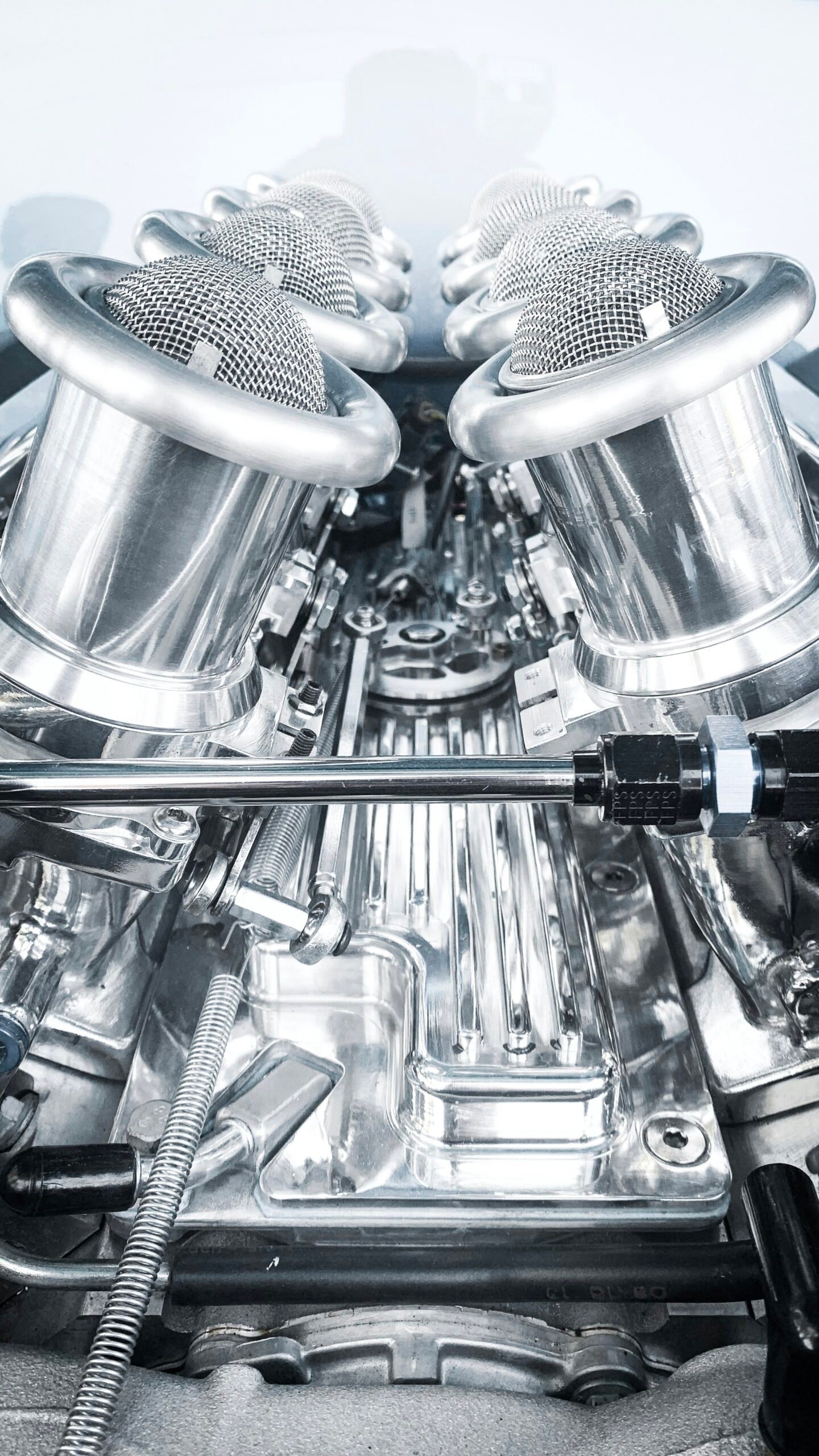

Key technologies underpinning additive manufacturing include selective laser sintering (SLS) and fused deposition modeling (FDM). SLS employs a laser to sinter powdered materials, binding them together to create durable parts, while FDM extrudes thermoplastic filaments to fabricate objects, both of which contribute significantly to the production of aerospace components. These techniques facilitate the creation of geometrically complex structures that can optimize performance and reduce overall weight, which is particularly crucial in the aerospace field where weight reduction leads to increased fuel efficiency and reduced emissions.

The benefits of additive manufacturing extend beyond its technical capabilities. The potential for significant cost savings is particularly notable, as AM can decrease material waste and shorten lead times for prototyping and production. Historically, the adoption of AM in aerospace began in limited applications, primarily for prototyping purposes. However, in recent years, the industry has recognized the value of 3D printing for end-use parts, with major players integrating this technology into their manufacturing processes. As aerospace manufacturers continue to embrace additive manufacturing, it is likely to play a vital role in driving innovation and improving operational efficiency.

Benefits and Challenges of Additive Manufacturing in Aerospace Components

Additive manufacturing (AM) has emerged as a transformative technology in the aerospace industry, revolutionizing the way components are designed and produced. One of the most significant advantages of AM is the ability to create complex geometries that were previously unattainable with traditional manufacturing methods. This layer-by-layer fabrication process allows for intricate designs that optimize weight and performance, leading to enhanced fuel efficiency and overall aircraft performance.

Further, additive manufacturing promotes material efficiency. By using only the necessary amount of material, AM minimizes waste and enables the use of advanced materials that can improve the durability and functionality of components. This is particularly important in aerospace applications, where every ounce counts and any reduction in excess material can lead to substantial cost savings over the lifecycle of an aircraft.

Another notable benefit is the significant reduction in lead times. With additive manufacturing, prototypes and production parts can be created rapidly, shortening the overall time from design to deployment. This agility enables aerospace companies to respond faster to market demands and innovate more swiftly, resulting in a competitive edge.

Despite these advantages, several challenges accompany the integration of additive manufacturing in the aerospace sector. One primary concern is regulatory compliance, as aerospace components must adhere to stringent safety and quality standards. Ensuring that newly manufactured parts meet these regulations can complicate the implementation of AM technologies.

Material limitations are another obstacle; not all materials are suitable for additive manufacturing processes, which can restrict design strategies and performance capabilities. Additionally, there is a pressing need for skilled operators who understand the complexities of AM and can effectively manage production processes. Ensuring a qualified workforce is essential for the long-term success of additive manufacturing in aerospace.

Real-life case studies highlight the potential of additive manufacturing, showcasing successful implementations in leading aerospace companies. These instances provide valuable insights into the hurdles faced and lessons learned, showcasing both the promise and the challenges of incorporating this technology into aerospace practices.

Current Applications of Additive Manufacturing in Aerospace

In recent years, additive manufacturing (AM), commonly known as 3D printing, has gained substantial traction within the aerospace industry. Leading companies such as Boeing, Airbus, and GE Aviation have began integrating this innovative technology into their production processes. The versatile nature of AM allows for the creation of complex geometries, which is particularly advantageous in aerospace component design.

Boeing has adopted additive manufacturing for various components, primarily focusing on engine parts and interior structures. For instance, the company utilizes 3D printing to produce lightweight components that contribute to fuel efficiency and overall performance. These parts, produced using materials like titanium and polymer, are used in commercial aircraft, enhancing their structural integrity while reducing weight.

Similarly, Airbus is leveraging additive manufacturing to prototype and produce components for its A350 XWB aircraft. The company has explored the fabrication of cabin parts and structural elements, utilizing AM to streamline production processes and reduce lead times. By implementing 3D printing technologies, Airbus can experiment with cutting-edge designs that would be impractical or overly expensive to produce using traditional methods.

GE Aviation stands at the forefront of additive manufacturing in the sector by fabricating intricate engine components, such as fuel nozzles and brackets. The use of AM has enabled GE to consolidate the number of parts needed, leading to considerable reductions in weight and cost. Moreover, by utilizing AM in replacement parts, the maintenance process becomes more efficient, allowing for on-demand production and reduced inventory costs.

The introduction of additive manufacturing in aerospace not only enhances component production but also reshapes the supply chain. As manufacturers rely more on 3D printing, the traditional supply chains are evolving, emphasizing localized production and shorter delivery times. This shift influences maintenance practices, facilitating more effective responses to component failures and the need for replacements in an increasingly dynamic aviation environment.

The Future of Additive Manufacturing in Aerospace: Trends and Innovations

The aerospace sector is on the brink of transformation, driven by significant advancements in additive manufacturing (AM) technology. One of the most notable trends in this field is the development of high-performance alloys and composite materials tailored specifically for aerospace applications. These advanced materials not only enhance strength-to-weight ratios but also improve resistance to extreme temperatures and corrosive environments, making them ideal for critical aerospace components.

In conjunction with material advancements, the integration of automation and digital manufacturing processes is revolutionizing production efficiency. Techniques such as robotic additive manufacturing allow for complex geometries to be constructed with precision and speed, reducing lead times while maintaining quality. Furthermore, digital twin technology is emerging as a game-changer, allowing manufacturers to create virtual replicas of components for predictive maintenance and optimization, thereby minimizing downtime and costs.

Artificial intelligence (AI) is also playing a significant role in the future of additive manufacturing within aerospace. AI-driven algorithms are being utilized to enhance design processes through generative design, where software explores a multitude of design alternatives based on predefined constraints. This not only speeds up the development phase but also aids in optimizing material usage and performance criteria. Moreover, AI is helping manufacturers streamline production processes, monitor quality, and foresee potential issues before they arise.

As these innovations continue to shape the aerospace manufacturing landscape, the implications for sustainability are noteworthy. The ability to produce parts on demand reduces excess inventory and waste, aligning with global sustainability goals. Moreover, regulatory bodies are beginning to take notice of these advancements, potentially paving the way for new standards that prioritize safety while accommodating innovative practices. The future of additive manufacturing in aerospace is positioned not only to enhance operational efficiencies but also to contribute positively to environmental objectives, setting a precedent for industries beyond aerospace.