Understanding 3D Printing Technology

3D printing, also known as additive manufacturing, is a revolutionary technology that constructs three-dimensional objects by layering materials based on digital models. This process begins with the creation of a computer-aided design (CAD) file, which serves as the blueprint for the object. The subsequent layers are formed by depositing materials in a precise manner, allowing for intricate designs and complex geometries that are often unattainable through traditional manufacturing methods.

Various 3D printing techniques are employed in the manufacturing sector, with the most common types being Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). FDM works by extruding melted thermoplastic filament through a nozzle, which cools and solidifies layer by layer. SLA, on the other hand, utilizes a laser to cure liquid resin into hardened plastic, ideal for high-resolution models. SLS involves the use of lasers to fuse powdered materials into solid structures. Each of these techniques offers unique advantages and can be tailored to different applications within the medical field.

One of the primary benefits of 3D printing lies in its ability to create highly customized medical devices tailored to individual patient needs. Unlike traditional manufacturing, which often requires extensive tooling and setup, 3D printing allows for rapid prototyping and iterations, significantly reducing lead times. Furthermore, since it operates on a layer-by-layer approach, complex and lightweight structures can be produced with less waste compared to subtractive manufacturing methods.

In the realm of healthcare, materials used in 3D printing are crucial for the safety and functionality of medical devices. Biocompatible plastics and metals, such as titanium and medical-grade polymers, are commonly utilized to ensure that devices can be safely integrated into the human body. This compatibility is essential for applications ranging from surgical instruments to custom implants, facilitating advancements in patient care.

Applications of 3D Printing in Medical Devices

The advent of 3D printing technology has brought transformative changes to various industries, and healthcare stands out as a significant beneficiary. In the realm of medical devices, 3D printing facilitates the creation of highly customized products that address individual patient needs. One prominent application is the development of patient-specific implants. These implants are tailored from biocompatible materials derived from detailed scans of the patient’s anatomy, ensuring a perfect fit that promotes optimal healing and integration within the body.

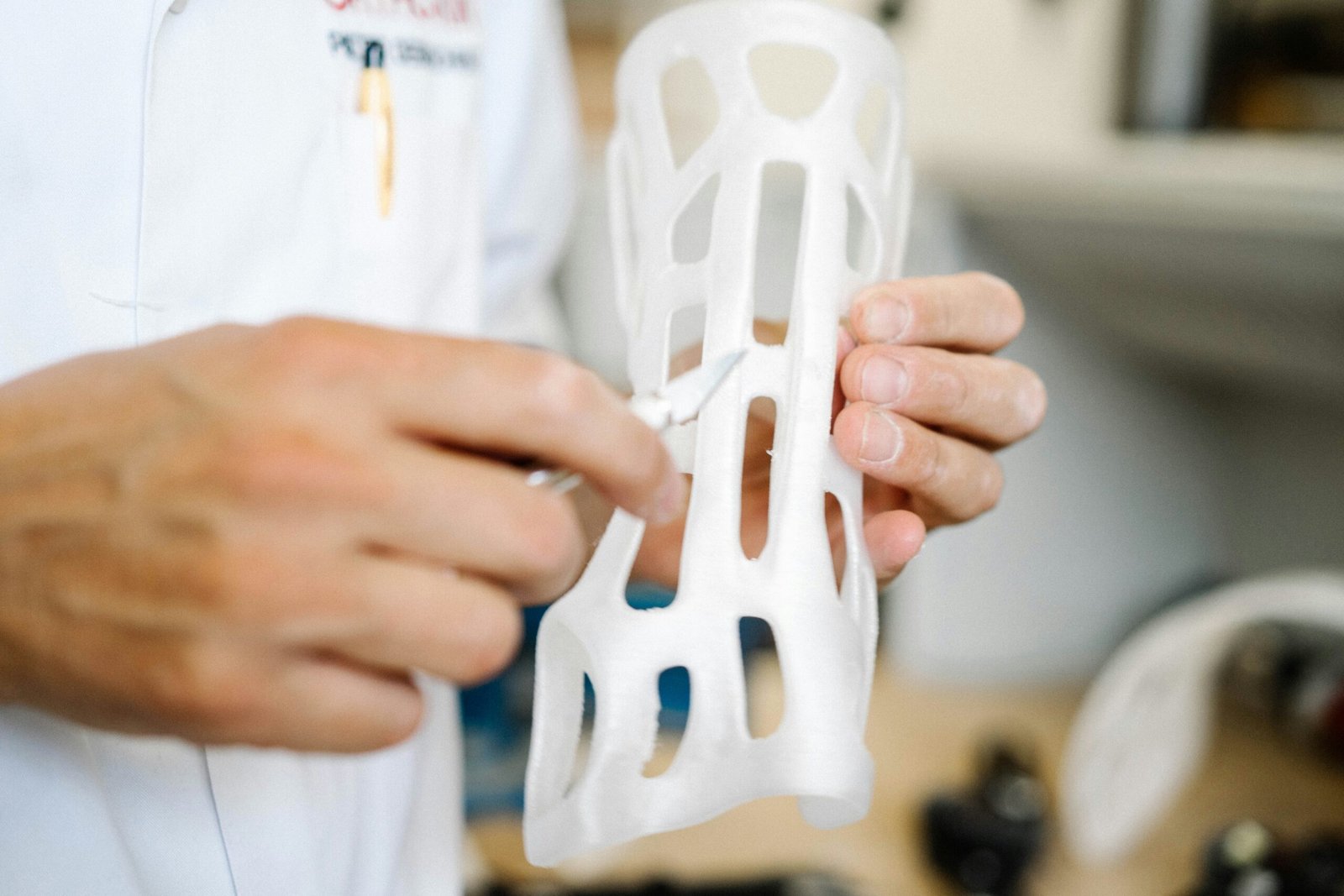

Another crucial application lies in the design and production of prosthetics. Traditional methods often result in generic solutions that may not adequately meet a patient’s requirements. However, 3D printing allows for the personalization of prosthetic limbs, enabling them to be lightweight, durable, and specifically shaped to match the unique anatomical contours of the user. This customization enhances comfort and functionality, leading to improved life quality for amputees.

Surgical instruments also benefit significantly from 3D printing technology. Surgeons can now possess tools manufactured using customized designs that improve surgical precision. For example, 3D-printed guides can help in the alignment and placement of implants during orthopedic surgeries, ultimately leading to better surgical outcomes.

Furthermore, anatomical models created through 3D printing have proven invaluable for surgical planning. These models provide a tangible representation of complex structures, allowing physicians to rehearse procedures prior to performing them on patients. This pre-surgical practice can lead to increased efficiency and reduced operation times, which in turn minimizes patient risk.

Overall, the applications of 3D printing in medical device manufacturing not only enhance patient outcomes but also streamline processes within the healthcare system. The continuous innovation in this field promises even greater advancements in medical practices, ensuring that patient-centric care remains at the forefront of healthcare developments.

Benefits and Challenges of 3D Printed Medical Devices

The integration of 3D printing technology within medical device manufacturing has ushered in numerous benefits that significantly enhance patient care and streamline production processes. One of the primary advantages is the capability for personalization. Medical devices can be tailored to meet the unique anatomical needs of individual patients, resulting in better-fitting implants and prosthetics. For instance, orthopedic surgeons have employed 3D printing to create custom implants that improve surgical outcomes and reduce recovery times.

Another significant benefit is the reduction in production costs. Traditional manufacturing methods often require extensive tooling and set-up, leading to higher expenses. In contrast, 3D printing allows manufacturers to create devices directly from digital files, minimizing material waste and decreasing overhead costs. This has made it financially feasible for small and emerging companies to enter the market and innovate contemporary solutions. Successful case studies, such as that of Lifelike Biotech, demonstrate how 3D printed models have transformed surgical planning, improving accuracy and reducing OR time.

Despite these advantages, the journey towards widespread adoption of 3D printed medical devices is not without its challenges. Regulatory hurdles pose a significant barrier, as the FDA and similar bodies require stringent testing and validation to ensure device safety and efficacy. Furthermore, quality control remains a critical issue, as the manufacturing process must consistently yield high-quality products that meet industry standards. Lastly, there is a pressing need for specialized training for healthcare professionals to navigate this rapidly evolving field. Understanding the technology and its implications on patient care is essential for maximizing the potential benefits of 3D printed devices.

The Future of 3D Printing in Healthcare

The future of 3D printing in healthcare holds immense potential, primarily driven by advancements in technology, research, and collaboration among various stakeholders. One notable area of growth is bioprinting, which involves the layer-by-layer deposition of living cells to create tissues that can mimic the function of natural biological structures. This innovation could revolutionize regenerative medicine, enabling the development of organs for transplantation and reducing the reliance on donor organs. As techniques improve, bioprinting might even allow for the customization of tissues that are tailored to individual patients’ needs, promising better outcomes and fewer complications.

Ongoing research is pivotal in expanding the applications of 3D printing in healthcare. Institutions around the globe are exploring how to further implement this technology in surgical planning, where patient-specific anatomical models can be produced. These models enable surgeons to practice complex procedures before operating on real patients, potentially leading to increased success rates. Moreover, the ability to print bespoke medical devices, such as prosthetics and implants, is becoming more accessible, resulting in better fitting and improved patient comfort.

The potential for widespread adoption of 3D printing in medical institutions is significant. However, this transition will require collaboration between engineers, healthcare professionals, and regulatory bodies to ensure safety and effectiveness standards are met. The development of guidelines and protocols will be crucial in addressing the challenges that arise from introducing 3D-printed products into clinical practice. As partnerships grow among these actors, the integration of 3D printing into the healthcare landscape will likely accelerate, paving the way for innovative solutions that enhance patient care while optimizing resource use.