Understanding Generative AI in Metal Design

Generative AI refers to a class of artificial intelligence systems that utilize algorithms to create new content or designs based on rules and data input. In the context of metal design, generative AI facilitates the development of innovative structures that may not be easily conceived through traditional design methods. By leveraging advanced computational techniques, these algorithms can analyze vast datasets to discover patterns, identify constraints, and optimize designs according to predefined objectives.

The technology behind generative AI in metal design primarily involves generative design software that operates on principles of iterative refinement. Designers input parameters such as material specifications, manufacturing processes, and performance criteria, after which the software utilizes algorithms to generate a multitude of design alternatives. This capability not only speeds up the design phase but also promotes creative exploration by presenting options that may challenge conventional aesthetics or functionality.

Applications of generative AI in metal design are diverse, ranging from automotive and aerospace engineering to medical devices and architectural components. For instance, companies like Autodesk and Siemens have developed software tools that allow engineers to create lightweight yet structurally sound metal components. These tools harness generative algorithms to consider factors like stress distribution and weight reduction, resulting in designs that optimize resource use without compromising performance.

Moreover, generative AI enhances creativity and efficiency within the design process by enabling designers to explore more possibilities than would be feasible manually. By removing time-consuming tasks and facilitating rapid prototyping through simulation, these AI systems allow professionals to focus on critical decision-making aspects, ultimately leading to the production of highly innovative and functional metal designs.

Benefits of Implementing Generative AI in Metal Design

The integration of generative AI into metal design processes presents a myriad of advantages that significantly enhance efficiency and innovation. One of the primary benefits is the reduction in design time. Traditional design methodologies often involve numerous iterations and trials; however, generative AI expedites this procedure by allowing engineers to input parameters and constraints, subsequently generating multiple design alternatives. This not only accelerates the design phase but also provides unique solutions that may have been overlooked in a conventional setup.

Improved performance is another critical advantage of employing generative AI in metal design. By utilizing advanced algorithms, the AI can simulate various operational scenarios, thereby identifying the most effective design configurations. This leads to products that not only meet but exceed performance standards, resulting in heightened durability and functionality. Moreover, these optimized designs can significantly enhance the structural integrity of metal products, ensuring better performance under stress and strain.

Moreover, the optimization of material usage is a noteworthy benefit. Generative AI analyzes and identifies the most efficient ways to utilize materials, reducing waste. This is particularly essential in metal design, where material costs can be significant. By minimizing waste and enhancing material efficiency, businesses can realize substantial cost savings, thus improving their bottom line. A case in point is a renowned aerospace manufacturer that implemented generative AI, resulting in a 30% reduction in material costs alongside improved product performance.

Incorporating generative AI in metal design is not merely a trend; it is a transformative approach that promises long-term benefits. The evidence from various case studies, including those in the automotive and aviation sectors, underscores the advantages of this technology, making it an essential consideration for businesses aiming to remain competitive in the marketplace.

Challenges and Limitations of Generative AI in Metal Design

Generative AI has emerged as a groundbreaking tool in the realm of metal design, promising enhanced efficiency and creativity in manufacturing processes. However, its implementation is not without significant challenges and limitations. One primary technical challenge lies in data quality. High-quality datasets are essential for training generative AI models; however, many organizations struggle with incomplete, biased, or poorly structured data. Inaccurate data can lead to unreliable algorithms, producing designs that fail to meet necessary specifications or performance criteria.

Moreover, algorithm reliability poses another technical hurdle. Generative AI solutions often require extensive testing and validation to ensure their outputs are safe and feasible for real-world applications. The variability inherent in generative models can lead to unpredictable results, necessitating additional oversight and refinement to achieve desired outcomes. Thus, the success of generative AI in metal design heavily relies on rigorous data management practices.

Beyond technical challenges, organizational obstacles significantly hinder the adoption of generative AI in this sector. A notable issue is the skill gap, as many engineers and designers may lack familiarity with AI technologies. This lack of expertise can create resistance to change, as professionals may be hesitant to embrace unfamiliar tools over traditional design methods. Furthermore, the integration of AI into existing workflows often requires a cultural shift within organizations, which can be met with skepticism or reluctance.

To overcome these challenges, organizations should invest in training programs to enhance employee skills in AI methodologies. Encouraging a collaborative environment can also help foster innovation while addressing resistance. By addressing both technical and organizational barriers, businesses can maximize the potential of generative AI in metal design, paving the way for its successful implementation in manufacturing processes.

The Future of Metal Design: Trends and Innovations with Generative AI

The integration of generative AI into metal design is set to redefine the manufacturing landscape significantly. As industries continue to seek efficiencies and innovations, generative AI offers advanced computational capabilities that can enhance design processes in unprecedented ways. One of the prominent trends includes the shift towards sustainability, as generative AI enables designers to create optimally efficient structures that use less material without compromising integrity. This not only leads to cost savings but also aligns with the global emphasis on reducing waste and environmental impact.

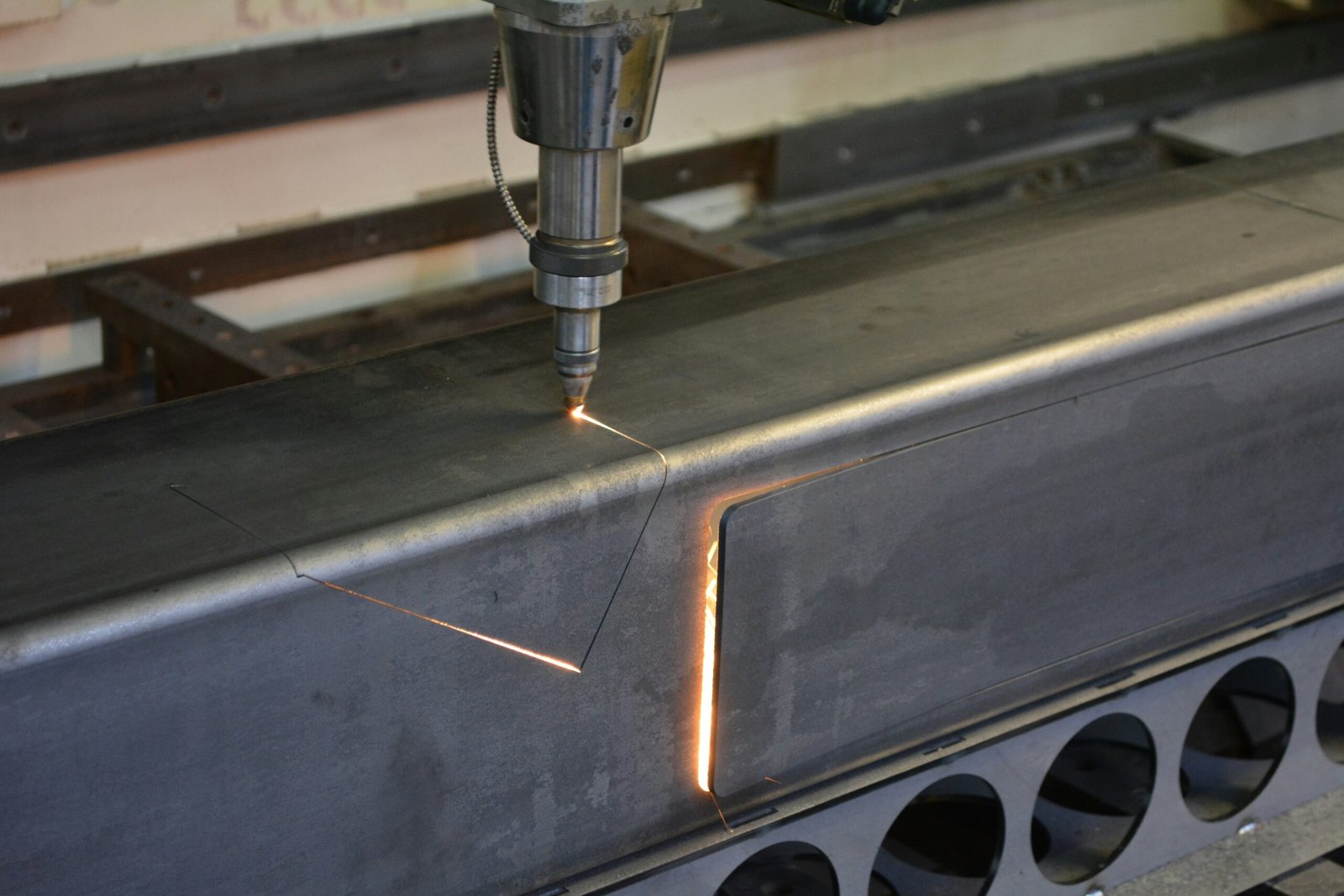

Another critical innovation is the enhancement of additive manufacturing techniques, such as 3D printing, where generative AI algorithms can optimize the design for various factors like strength, weight, and manufacturability. This allows for the creation of complex geometries that were previously unattainable through traditional methods. In this context, generative AI aids in simulating various design options, allowing for rapid prototyping and the ability to iterate designs swiftly. The implications for manufacturers involve shorter production times and increased flexibility in responding to market demands.

Furthermore, the role of collaborative design tools, enhanced by AI, is expected to gain traction. These tools enable multidisciplinary teams to engage in a more interactive design process, where engineers, designers, and AI coalesce to explore new ideas and innovations. This collaboration may involve real-time feedback mechanisms driven by data analysis and machine learning, presenting opportunities for refining designs based on performance predictions.

Experts predict that the future of metal design will extend beyond mere aesthetics or mechanical functionality, incorporating intelligent design that adapts to user needs and environmental conditions. As we move forward, the continuous evolution of generative AI will empower designers and manufacturers alike to push the boundaries of what is possible in metal design, leading to a more innovative, efficient, and responsive manufacturing industry.