Introduction to Process Engineering Trends

Process engineering stands as a critical discipline within various industries, focused on the design, optimization, and management of processes that convert raw materials into valuable products. This profession encompasses a wide range of sectors including manufacturing, pharmaceuticals, energy, and food production, highlighting its versatility and importance in today’s economy. The primary objective of process engineering is to streamline workflows, enhance product quality, and significantly reduce operational costs, thereby contributing to the overall efficiency and sustainability of organizations.

In essence, process engineers analyze, design, and improve industrial processes, ensuring they are not only effective but also economically viable. Utilizing principles from chemical and mechanical engineering, along with advanced modeling techniques, process engineers are tasked with identifying inefficiencies and implementing innovative solutions. With the increasing emphasis on sustainability and environmental stewardship, the role of process engineering is expanding, incorporating green technologies and practices aimed at minimizing waste and energy consumption.

The significance of process engineering has grown substantially in recent years, especially in a rapidly evolving technological landscape. Companies are increasingly leveraging automation, data analytics, and artificial intelligence to refine their processes, making it essential for professionals in the field to remain adaptable and forward-thinking. As we look ahead to 2025, various trends are anticipated to shape the future of process engineering, offering new opportunities for innovation and improvement. Understanding these emerging trends will be vital for industries seeking to maintain a competitive edge while meeting both consumer demands and regulatory standards.

By exploring these anticipated changes in process engineering, stakeholders can prepare for shifts in methodologies and practices, ensuring they remain aligned with industry advancements and societal expectations. This examination will not only highlight what is on the horizon but also emphasize the ongoing importance of the discipline in driving operational excellence across multiple sectors.

Key Trends Shaping Process Engineering in 2025

The field of process engineering is rapidly evolving, with various trends set to redefine operational paradigms by 2025. One significant advancement is the rise of automation and digitalization. The adoption of automated systems and digital platforms facilitates streamlined operations, maximizing efficiency and reducing human error. Process engineers are increasingly leveraging robotics and automation technologies, enabling faster production cycles and minimizing costs, which is crucial for maintaining competitive advantages.

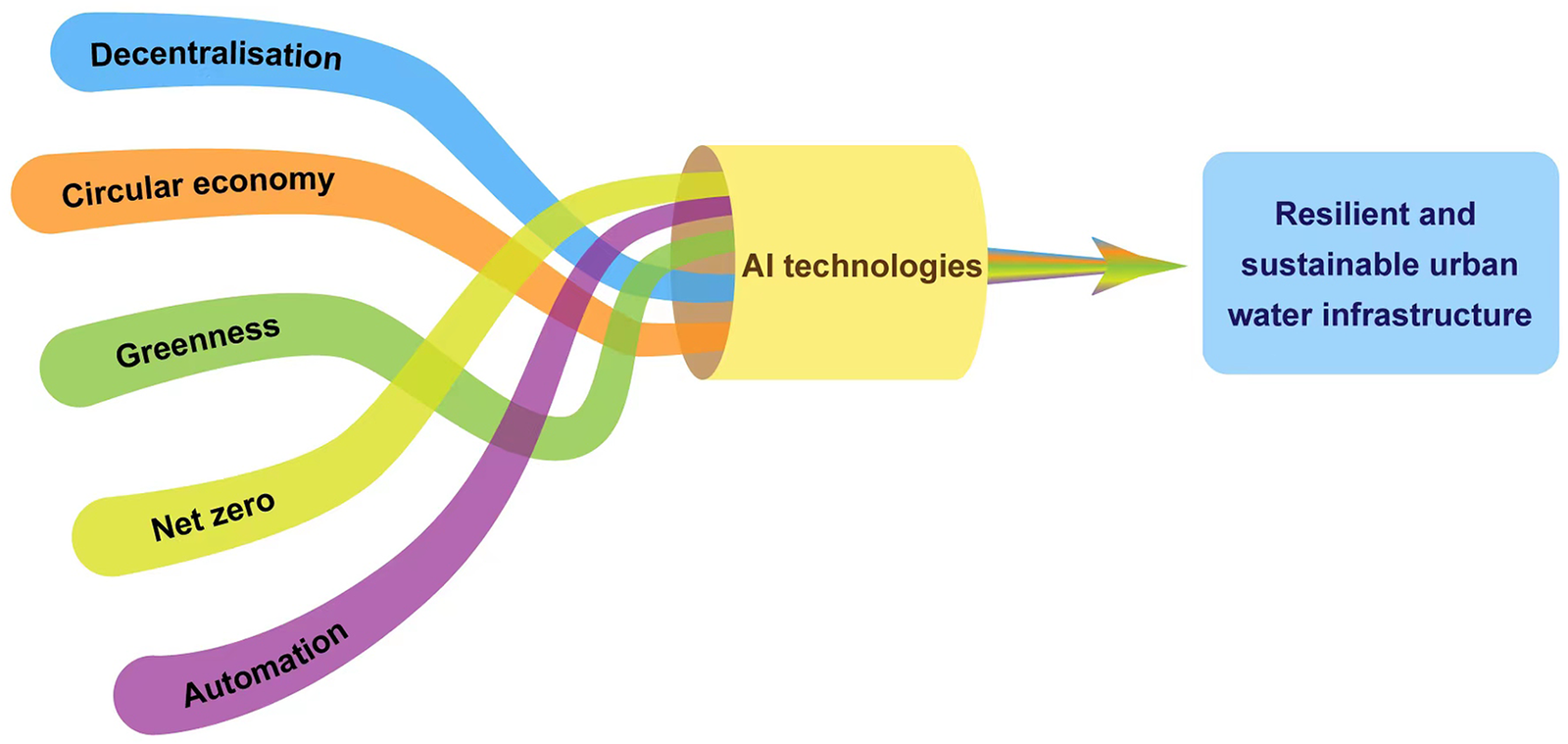

Another pivotal trend is the integration of artificial intelligence (AI) and machine learning. These technologies offer process engineers the capability to analyze vast amounts of data, leading to improved decision-making processes. By harnessing predictive analytics and intelligent algorithms, organizations can optimize production schedules, enhance resource allocation, and identify potential bottlenecks in real-time. This shift not only boosts productivity but also paves the way for innovative solutions in process design and execution.

Moreover, sustainable engineering practices are gaining traction. The focus on sustainability is influencing process engineering, with engineers adopting methods that minimize environmental impact. This includes the implementation of energy-efficient systems and waste reduction initiatives, reflecting a broader commitment to responsible engineering. By embracing sustainable practices, organizations can achieve compliance with regulatory standards while improving their brand reputation among environmentally-conscious stakeholders.

Finally, the rise of smart manufacturing signifies a dramatic shift in how products are created. Smart factories utilize interconnected devices and systems to enhance visibility throughout the supply chain, resulting in better tracking and management of resources. This approach not only increases operational efficiency but also allows for greater customization, meeting the diverse demands of modern consumers. As these trends evolve, they will undoubtedly shape the landscape of process engineering, driving advancements and innovations essential for future success.

Survey Results: Insights from Industry Experts

In a recent series of surveys conducted among industry experts in the field of process engineering, a wealth of insights has emerged regarding the future landscape anticipated for 2025. Through active participation from professionals across various sectors, the survey aimed to capture the expectations, anticipated challenges, and areas of growth that these experts foresee. A significant focus was placed on technological innovations and their implications for the industry.

Data collected highlights that a considerable number of respondents believe that automation and artificial intelligence (AI) will play critical roles in shaping process engineering over the next few years. Over 60% of participants expressed optimism regarding the deployment of advanced automated systems to streamline workflows and enhance productivity. One expert noted, “The integration of AI not only improves process efficiency but also facilitates real-time data analysis, enabling us to make informed decisions quickly.”

Moreover, the respondents indicated that sustainability initiatives are increasingly becoming pivotal to the strategic planning of process engineering projects. Approximately 55% of experts forecast a rise in the demand for sustainable practices, emphasizing the need to reduce waste and energy consumption. As one industry leader articulated, “Incorporating eco-friendly methodologies is no longer an option but a necessity for companies aiming for longevity and market relevance.”

However, the survey also revealed challenges that professionals may face, particularly concerning workforce skill gaps. Many experts pointed out that while technology evolves rapidly, there is a pressing need for upskilling the current workforce to meet these technological advancements. “Organizations must invest in training programs to ensure that employees can harness new technologies effectively,” advised a process engineering consultant.

The comprehensive insights derived from these surveys underscore the dynamic nature of the process engineering field. With advancements in technology combined with an unwavering focus on sustainability, stakeholders must remain adaptable and proactive to harness the full potential of impending changes by 2025.

Preparing for the Future: Strategies for Adapting to Trends

As organizations navigate the ever-evolving landscape of process engineering, it becomes critical to adopt effective strategies that foster adaptability to emerging trends. One of the foremost actions companies can take is to invest in upskilling their workforce. Continuous professional development not only enhances employee competency but also aligns their skills with the latest technological advancements. This can be achieved through targeted training programs, workshops, and online courses that focus on emerging tools and methodologies relevant to process engineering.

Another essential strategy involves investing in new technologies. The rapid pace of innovation in the industry necessitates that organizations keep abreast of cutting-edge technologies, such as artificial intelligence, machine learning, and automation solutions, which are becoming increasingly integrated into process engineering practices. By piloting and implementing these advanced technologies, companies can optimize efficiency, reduce operational costs, and improve overall product quality. This proactive approach ensures that organizations remain at the forefront of their respective markets.

Furthermore, embracing a culture of continuous improvement is vital for organizations to adapt to changing trends. This can be operationalized through the adoption of methodologies such as Lean and Six Sigma, which focus on minimizing waste and enhancing process efficiency. By fostering an environment where feedback is actively sought and acted upon, organizations can encourage innovation and responsiveness to market demands.

Finally, collaboration is crucial in adapting to trends in process engineering. Companies should explore partnerships with other industries and academic institutions to leverage diverse expertise and insights. Collaborative efforts can lead to knowledge sharing, increased creativity, and the development of more effective solutions to complex challenges.

By implementing these pragmatic strategies, organizations can not only cope with the evolving landscape of process engineering but also position themselves advantageously in the marketplace.