Introduction to Chemical Process Optimization

Chemical process optimization is a crucial aspect of the chemical manufacturing industry, aimed at improving production efficiency, enhancing product quality, and reducing operational costs. This process involves the systematic adjustment of various parameters in chemical processes, enabling engineers to achieve the best possible outcomes from their operations. Traditional optimization methods primarily rely on empirical data, heuristics, and manual adjustments. These approaches, while effective to an extent, often fall short in addressing the complexities that arise within dynamic manufacturing environments.

One of the major challenges faced by chemical engineers is the inherent variability in chemical processes. Factors such as raw material quality, equipment performance, and environmental conditions can significantly influence the end product. Additionally, the intricate nature of chemical reactions often leads to non-linear behaviors, which can be difficult to predict and control. As a result, traditional optimization techniques may struggle to find the optimal balance among competing objectives, such as maximizing yield while minimizing production costs and ensuring safety standards.

The objectives of optimizing chemical processes encompass a range of factors essential for sustaining competitiveness in the market. Effective optimization can lead to substantial cost savings, reduce waste production, and minimize energy consumption, all of which contribute to a company’s bottom line. Moreover, improvements in process safety ensure the well-being of workers and the environment, while enhancing product quality can lead to increased customer satisfaction and loyalty. By addressing these goals, chemical process optimization not only enhances operational performance but also fosters innovation within the industry. Understanding these foundational aspects is critical as we explore the transformative role AI technology plays in revolutionizing chemical process optimization.

The Role of AI in Chemical Process Optimization

Artificial intelligence (AI) has emerged as a transformative force in various industries, and chemical process optimization is no exception. The integration of AI technologies, such as machine learning, neural networks, and optimization algorithms, has greatly enhanced the capabilities and efficiency of chemical processes. These advanced technologies analyze complex data sets, enabling the identification and prediction of optimal operational conditions that traditional methods may overlook.

Machine learning, a core component of AI, plays a crucial role in chemical process optimization by utilizing historical data to develop predictive models. These models help in forecasting outcomes based on varying input parameters, thus facilitating informed decision-making. For instance, machine learning algorithms can analyze experimental data from chemical reactions, identify trends, and recommend adjustments to reaction conditions for improved yields. This capability allows for a more efficient design of experiments, significantly reducing both time and resource consumption.

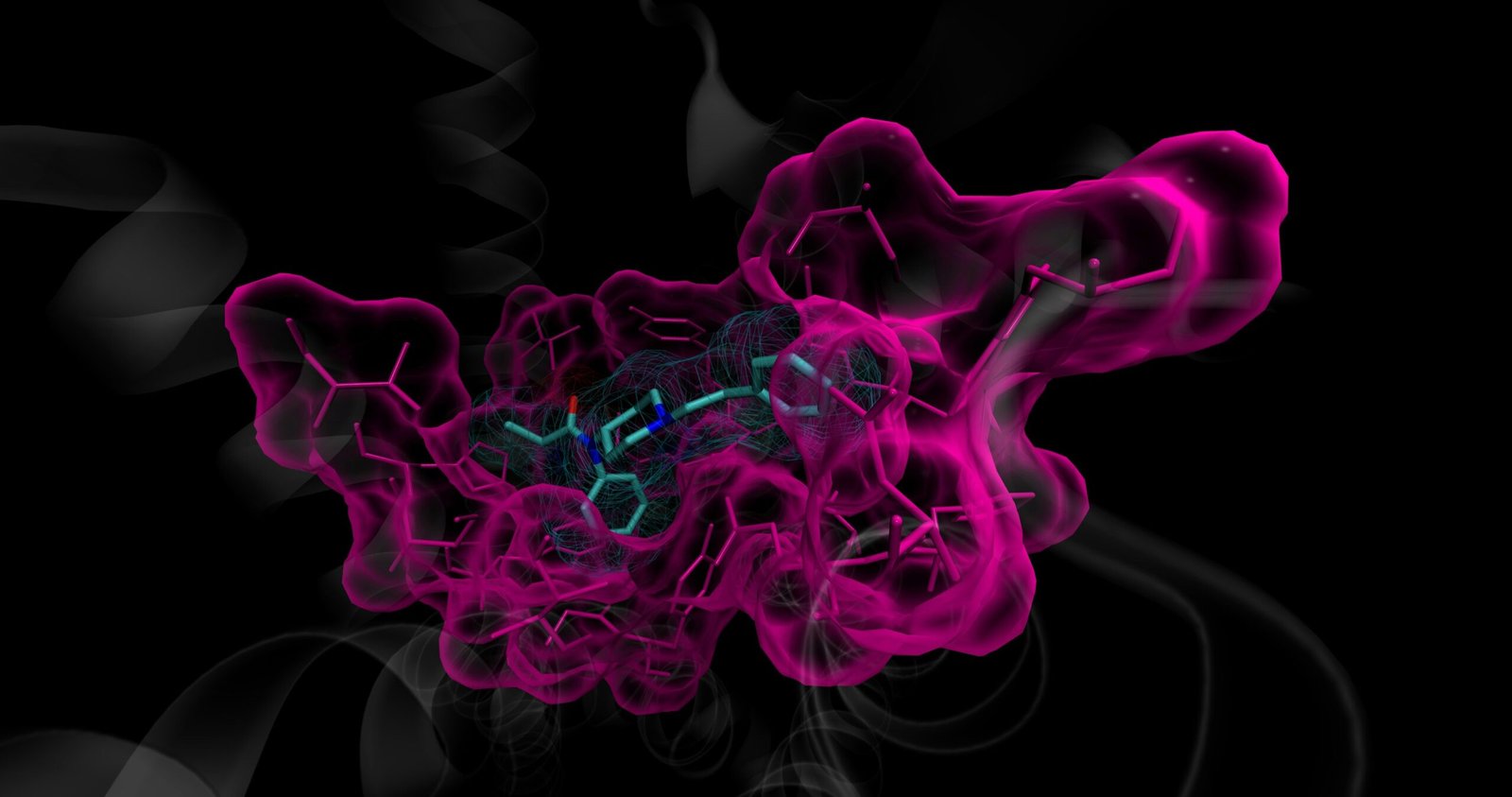

Neural networks, another vital aspect of AI, are particularly effective in managing non-linear relationships within data. By mimicking the functioning of the human brain, neural networks can interpret complex patterns that may not be identifiable through conventional analysis. This ability allows for the optimization of chemical processes by predicting how changes in parameters, such as temperature and pressure, influence product quality and efficiency. Additionally, these networks can adapt over time, continuously improving their predictions as more data becomes available.

Optimization algorithms further augment process efficiency by systematically exploring variable combinations to identify the most beneficial conditions. By integrating these algorithms within AI frameworks, operators can automate the optimization process, reducing the need for manual adjustments and accelerating the overall production cycle.

Real-world applications of AI in chemical process optimization have demonstrated significant improvements in productivity and sustainability. For example, AI-driven systems have optimized reaction pathways in pharmaceutical manufacturing, leading to reduced waste and lower production costs. Such successful implementations underscore the immense potential of AI to revolutionize chemical process optimization.

Benefits and Challenges of Implementing AI Solutions

The integration of Artificial Intelligence (AI) within the domain of chemical process optimization presents a multitude of advantages that can substantially enhance operational efficiency and decision-making capabilities. One of the foremost benefits is the ability of AI algorithms to analyze vast datasets rapidly, enabling chemists and engineers to identify inefficiencies and optimize reaction conditions with greater precision. By leveraging machine learning models, organizations can automate routine tasks such as monitoring process variables, thereby significantly reducing human error and increasing productivity.

Additionally, AI technologies contribute to waste reduction by optimizing resource use. Through simulation and predictive analytics, AI can forecast the outcomes of chemical processes, allowing for the fine-tuning of parameters that minimize byproduct generation and maximize yield. This not only benefits the environment but also helps organizations to achieve cost savings and adhere to sustainability goals, which are increasingly important in today’s industrial landscape.

Despite these considerable advantages, organizations face notable challenges when implementing AI solutions. Data quality issues could pose significant roadblocks; inconsistent, incomplete, or inaccurate data can severely diminish AI effectiveness. Furthermore, the adoption of AI technologies often encounters resistance to change from employees and management alike. Human factors can hinder the transition towards automated processes, necessitating comprehensive change management strategies that prioritize employee training and engagement.

Moreover, successful AI integration requires specialized skills that may not be readily available within the existing workforce. Organizations will often need to invest in training or recruit new talent, thereby incurring additional costs and resource allocation. Balancing these benefits and challenges is crucial for organizations aiming to revolutionize their chemical processes with AI technology, ensuring that they navigate this transformative journey effectively.

Future Trends and Innovations in AI for Chemical Processes

The future of artificial intelligence (AI) in chemical process optimization is poised to bring significant advancements that can transform the industry. One of the most promising trends is predictive maintenance, which utilizes AI algorithms to analyze data collected from equipment and systems. By predicting when maintenance is required, companies can minimize downtime and enhance overall efficiency. This proactive approach not only reduces operational costs but also prolongs the life of essential equipment, ensuring that chemical processes remain uninterrupted.

Another emerging trend is the implementation of real-time monitoring systems powered by AI. These systems utilize sensor data and machine learning techniques to analyze chemical processes as they unfold, allowing for dynamic adjustments to operating conditions. This capability leads to improved product quality and yield while reducing waste—a crucial factor in the sustainability efforts of chemical manufacturers. Furthermore, AI’s ability to process vast amounts of data in real time enables organizations to make informed decisions quickly, responding to changes in production conditions or market demands.

Additionally, the integration of AI with Internet of Things (IoT) technologies is expected to further enhance chemical process optimization. This convergence allows for a more interconnected and automated environment. IoT devices can collect and transmit data from various sensors across chemical plants, which AI can then analyze to optimize processes beyond current capabilities. The result is a highly adaptive and intelligent system that can continuously learn from environmental changes, improving its performance over time.

Looking ahead, innovations in AI, such as the development of advanced neural networks and deep learning models, are likely to unlock even greater possibilities in chemical processes. These technologies can drive optimization at an unprecedented scale and precision, paving the way for a more efficient, cost-effective, and sustainable chemical industry. As these trends evolve, the potential for AI to revolutionize chemical process optimization will continue to expand, marking a new era in the field.